Improves operational efficiency by delivering combined benefits of up to 50% downtime reduction

- Significantly reduces downtime, with up to 30% reduction.

- Increases MTBF by up to 20%.

- Decreases MTTR by up to 25%.

Reduce site visits with remote monitoring for productivity, maintenance optimization, and energy reduction in industrial applications.

Author: Miguel Bermeo-Ayerbe, Carlos Ocampo-Martinez, and Javier Diaz-Rozo

Title: Non-intrusive condition monitoring based on event detection and functional data clustering

Publication: Engineering Applications of Artificial Intelligence, vol. 124, p. 106625

Date: September 2023

Author: Miguel Bermeo-Ayerbe, Vincent Cocquempot, Carlos Ocampo-Martinez, and Javier Diaz-Rozo

Title: Remaining useful life estimation of ball-bearings based on motor current signature analysis

Publication: Reliability Engineering &System Safety, vol. 235, p. 109209

Date: July 2023

Author: Carlos Puerto-Santana, Concha Bielza, Javier Diaz-Rozo, Guillem Ramirez-Gargallo, Filippo Mantovani, Gaizka Virumbrales, Jesús Labarta and Pedro Larrañaga

Title: Asymmetric HMMs for Online Ball-Bearing Health Assessments

Publication: IEEE Internet of Things Journal, vol. 9, p. 20160-20177

Date: October 2022

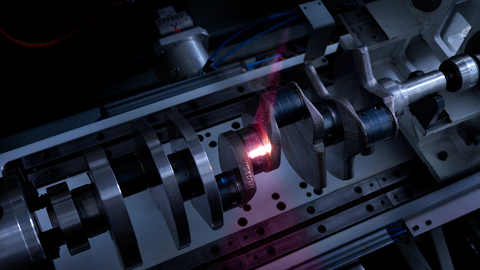

Author: D. Atienza, C. Bielza, J. Diaz-Rozo, and Pedro Larrañaga

Title: Efficient Anomaly Detection in a Laser-surface Heat-treatment Process via Laser-spot Tracking

Publication: IEEE/ASME Transactions on Mechatronics

Date: September 2020

Author: J. Diaz-Rozo, C. Bielza, y P. Larrañaga

Title: Machine-tool condition monitoring with Gaussian mixture models-based dynamic probabilistic clustering

Publication: Engineering Applications of Artificial Intelligence, vol. 89, p. 103434

Date: March 2020

Author: M. A. Montealegre, B. Arejita, P. Alvarez, C. Laorden, y J. Diaz-Rozo

Title: Control quality on process of laser heat treatment

Publication: Materials Science Forum, vol. 941, pp. 1860–1866.

Date: January 2019

Author: J. Diaz-Rozo

Title: Clustering probabilístico dinámico para la búsqueda de patrones de degradación de elementos de máquina en el ámbito del Industrie 4.0

Publication: PhD Thesis, Universidad Politécnica de Madrid

Date: September 2019

More information

More information

More information

More information

More information

More information