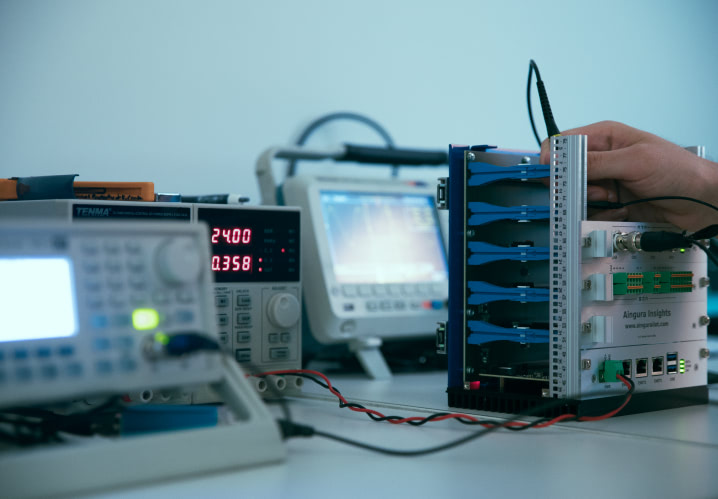

Maintenance

Working on failure prediction of the critical components requires to enter into an area of differential knowledge compared to the more general proposals on the market. The challenge arises because its development is based on the specific approach to the system and its process. In a first phase we monitor the degradation of the elements and estimate the remaining useful life. This solution allows the generation of maintenance policies that imply cost reduction, and which in a second phase, enables the implementation of predictive maintenance. Improvements in maintenance costs of between 10 and 40%, and increases in uptime (for machines) of between 2 and 25% have been estimated.

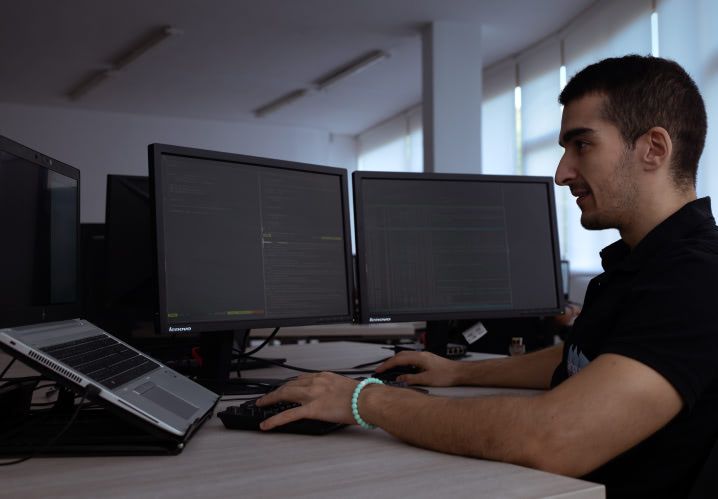

Condition Monitoring

Non stop condition monitoring solution can help to diagnose different problematics related to the asset. Additionally, it can also provide actionable insights that can be used by other type of applications, internal or external, such as simultaneous engineering (detection of critical components), degradation of assets, detection of failures, among others.

Consumption Efficiency

Thanks to the high speed analysis, consumption patterns can be obtained from energy, water, cooling, air and others. Our solution works synchronized with assets’ control systems and top notch Artificial Intelligence algorithms to provide actionable insights. These knowledge bits can help to maximize the overall efficiency in values higher than 10%, which can reach up to more than 50% in some states of use; and complying with specific process restrictions (such as quality, cycle times, etc.).

Quality Control

The quality control of the final product can be carried out in very different ways depending on the process, the materials, the objectives sought, among others. Our approach impacts on the quality of the manufactured component by being able to ensure the working condition of the machine, as well as the consolidation of the different variables for further analysis. Savings of up to 15% of the total cost of production have been achieved (by reducing claims), reducing destructive testing or by incorporating real time control of all parts without affecting the production process.