Participants

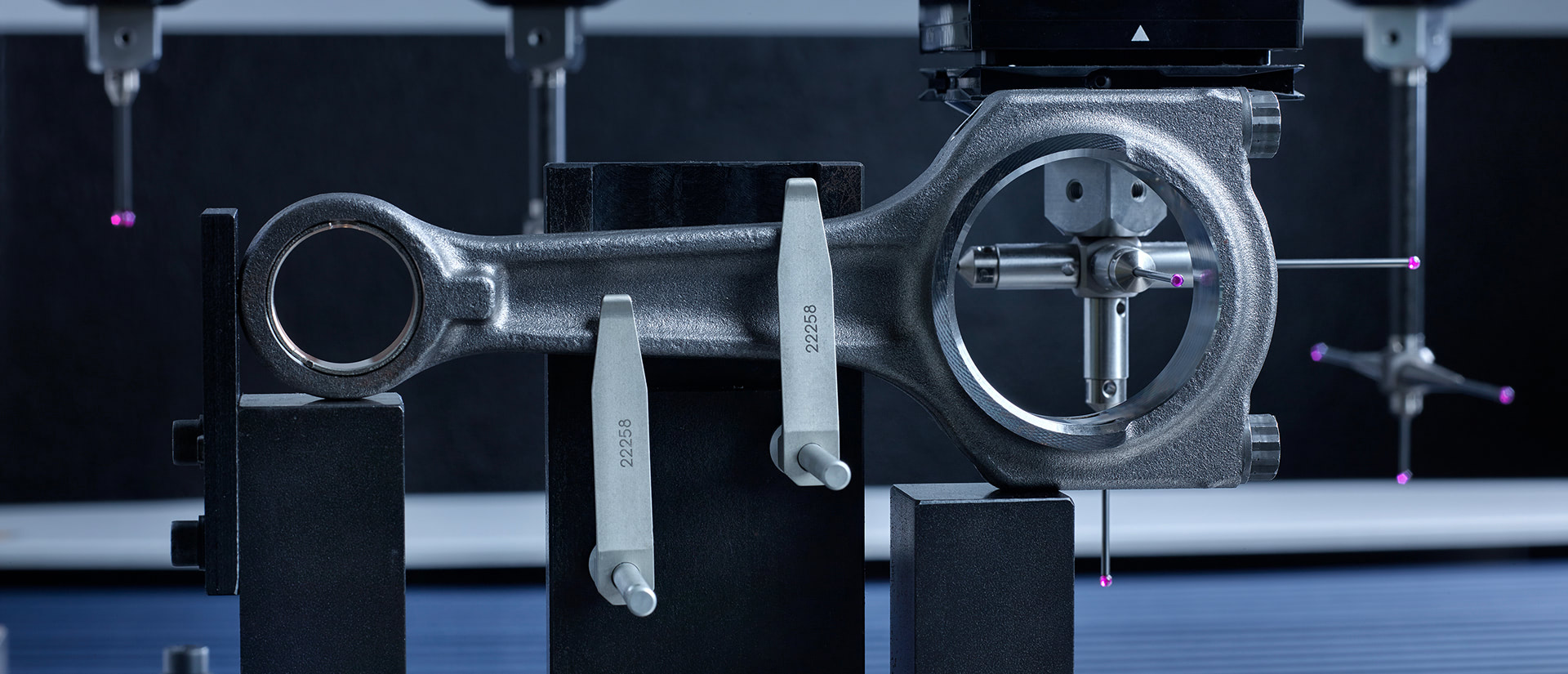

Etxetar

Universidad Politécnica de Madrid

impact

- 8% improvement in machine availability.

- Improved machine design by detecting the part of the machine that is most sensitive to thermal changes.

Developed AI Technologies

- Data intelligence.

- Smart sensors.

- Intelligent automation.

- Machine learning.

- Pattern analysis, prediction and intelligent classification.

Challenges

- To increase in machine availability in through high temperature gradients in production facilities. Due to these gradients, the machine/manufacturing line had to be idle around 2 hours.

- Support to the PLC/CNC compensation system to withstand extreme temperature changes.

- Improvement of the machine design according to the study of the sensitivity of different parts of the machine to extreme changes in temperature in a real productive environment.

- To complement analyzes done with finite elements during the machine design phase.

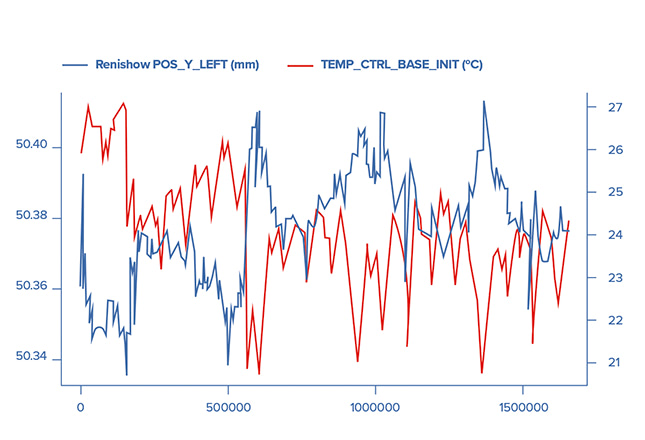

results

- Dataset size: 2GB

- Number of variables: 15

- Sampling time: 100ms

- Development of the first unattended system for the acquisition and pre-processing of machine data and interaction with the PLC.

- A predictive system for tool tip positioning has been developed.

- Development of an off-line variable selection model.

- Development of a multi-output regression model for continuous variables of temperature and flow.