As the IIoT technology is in continuous development, our commitment is to disseminate through high end publications, such as, indexed journal articles, books, patents and more. It will also help us to showcase our deep knowledge in our core technology activities in the field of Artificial Intelligence and High Performance Computing applied to different sectors.

Know how

Our know how is based on deep knowledge about Artificial Intelligence and High Performance Computing together with a well grounded industrial expertise.

We see what other do not see

Our solutions are based on high quality data oriented to the specific application. This approach helps us to see better than others all added value information.

We find what others do not find

Our extensive knowledge in Artificial Intelligence helps us to detect critical information for the specific tasks in terms of anomalies, degradation and failures. This approach of applied Artificial Intelligence to industry help us to find information better than others.

We understand what others do not understand

Our well grounded industrial expertise mixed our multidisciplinary team, being a mixture of different engineering disciplines, mathematicians and data analysts, help us to correlate what is found in the data with real specific solutions.

We reduce costs

Our technology helps us to detect specific pattern behaviors that potential create an increase in costs, such as, failures, early degradation or sub optimal behavior patterns.

We increase productivity

Our technology helps to reduce downtimes with direct impact on the productivity. This technology help to increase the productivity with condition monitoring and maintenance applications.

We optimize resources

Our technology analyze and monitors different resource consumption pattern in order to detect potential anomalies and unexpected large resource consumer, for example, if the element has a potential malfunction.

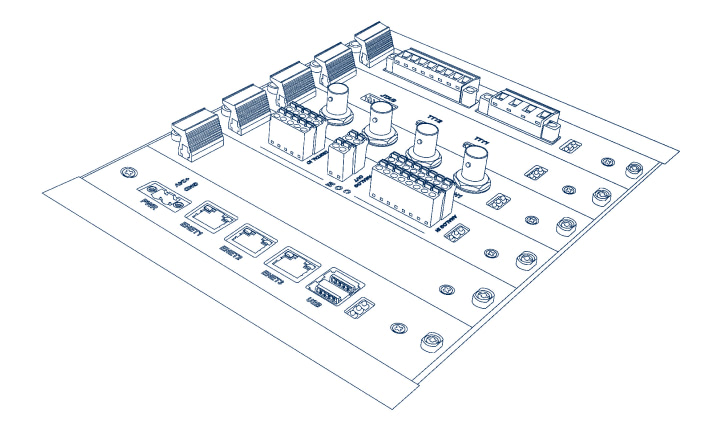

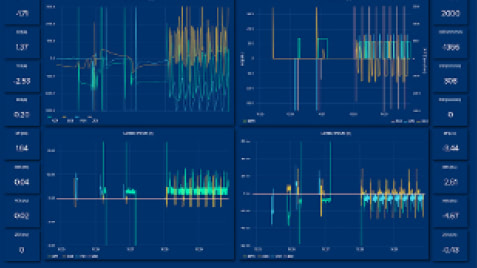

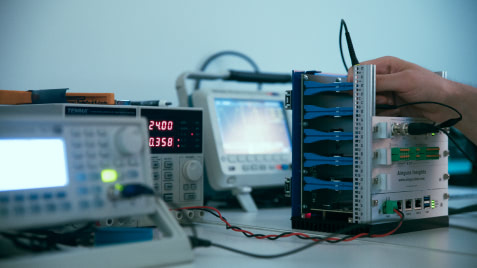

Aingura Insights

The Aingura Insights (AI) computing module, 100% design and developed by Aingura IIoT , provides a unique platform that guarantees the data quality. This embedded technology system used proprietary top notch technologies for distributed and high performance computing. The AI module complies with all requirements needed for data acquisition, pre processing, processing and actionable insight delivery phases performed at the Edge.

Publications

Industrial Applications of Machine Learning shows how machine learning can be applied to address real-world problems in the fourth industrial revolution, and provides the required knowledge and tools to empower readers to build their own solutions based on theory and practice. The book introduces the fourth industrial revolution and its current impact on organizations and society. It explores machine learning fundamentals, and includes four case studies that address a real-world problem in the manufacturing or logistics domains, and approaches machine learning solutions from an application-oriented point of view. The book should be of special interest to researchers interested in real-world industrial problems.

Author: J. Diaz-Rozo , J. J. Gabilondo

Title: Device and system including multiple devices for supervision and control of machines in industrial installation

Number: DE112018001085T5

Date: November 2019

Author: J. Diaz-Rozo , J. J. Gabilondo

Title: Device and system including multiple devices for supervision and control of machines in industrial installation

Number: US10317888B2

Date: June 2019

Author: J. Diaz-Rozo , J. J. Gabilondo

Title: Device and system including multiple devices for supervision and control of machines in industrial installation

Number: US10031500B1

Date: July 2018

Author: Miguel Bermeo-Ayerbe, Carlos Ocampo-Martinez, and Javier Diaz-Rozo

Title: Non-intrusive condition monitoring based on event detection and functional data clustering

Publication: Engineering Applications of Artificial Intelligence, vol. 124, p. 106625

Date: September 2023

Author: Miguel Bermeo-Ayerbe, Vincent Cocquempot, Carlos Ocampo-Martinez, and Javier Diaz-Rozo

Title: Remaining useful life estimation of ball-bearings based on motor current signature analysis

Publication: Reliability Engineering &System Safety, vol. 235, p. 109209

Date: July 2023

Author: Cristian Puerto-Santana, Carlos Ocampo-Martinez, and Javier Diaz-Rozo

Title: Mechanical rotor unbalance monitoring based on system identification and signal processing approaches

Publication: Journal of Sound and Vibration, vol. 541, p. 117313

Date: December 2022

Author: Carlos Puerto-Santana, Concha Bielza, Javier Diaz-Rozo, Guillem Ramirez-Gargallo, Filippo Mantovani, Gaizka Virumbrales, Jesús Labarta and Pedro Larrañaga

Title: Asymmetric HMMs for Online Ball-Bearing Health Assessments

Publication: IEEE Internet of Things Journal, vol. 9, p. 20160-20177

Date: October 2022

Author: M. Bermeo-Ayerbe, Carlos Ocampo-Martinez, and J. Diaz-Rozo

Title: Data-driven energy prediction modeling for both energy efficiency and maintenance in smart manufacturing systems

Publication: Journal of Energy, vol. 238, p. 121691

Date: January 2022

Author: M. Bermeo-Ayerbe, Carlos Ocampo-Martinez, and J. Diaz-Rozo

Title: Adaptive predictive control for peripheral equipment management to enhance energy efficiency in smart manufacturing systems

Publication: Journal of Cleaner Production, vol. 291, p. 125556

Date: April 2021

Author: D. Atienza, C. Bielza, J. Diaz-Rozo, and Pedro Larrañaga

Title: Efficient Anomaly Detection in a Laser-surface Heat-treatment Process via Laser-spot Tracking

Publication: IEEE/ASME Transactions on Mechatronics

Date: September 2020

Author: J. Diaz-Rozo, C. Bielza, y P. Larrañaga

Title: Machine-tool condition monitoring with Gaussian mixture models-based dynamic probabilistic clustering

Publication: Engineering Applications of Artificial Intelligence, vol. 89, p. 103434

Date: March 2020

Author: M. A. Montealegre, B. Arejita, P. Alvarez, C. Laorden, y J. Diaz-Rozo

Title: Control quality on process of laser heat treatment

Publication: Materials Science Forum, vol. 941, pp. 1860–1866.

Date: January 2019

Author: J. Diaz-Rozo

Title: Clustering probabilístico dinámico para la búsqueda de patrones de degradación de elementos de máquina en el ámbito del Industrie 4.0

Publication: PhD Thesis, Universidad Politécnica de Madrid

Date: September 2019

Author: J. L. Diaz, M. Bermeo, J. Diaz-Rozo, y C. Ocampo-Martinez

Title: An optimization-based control strategy for energy efficiency of discrete manufacturing systems

Publication: ISA Transactions, vol. 93, pp. 399-409

Date: October 2019

Author: Ying hao Xu, Miquel Vidal, Beñat Arejita, Javier Diaz-Rozo, Carlos Alvarez, Daniel Jiménez-González, Xavier Martorell, Filippo Mantovani

Title: Implementation of the K-Means Algorithm on Heterogeneous Devices: A Use Case Based on an Industrial Dataset

Publication: vol. 32, pp. 642-651

Date: January 2018

Author: J. Diaz-Rozo, C. Bielza, y P. Larrañaga

Title: Clustering of data streams with dynamic Gaussian mixture models: An IoT application in industrial processes

Publication: IEEE Internet of Things Journal, vol. 5, n.o 5, pp. 3533-3547

Date: October 2018

Author: A. Ogbechie, J. Diaz-Rozo, P. Larrañaga, y C. Bielza

Title: Dynamic Bayesian network-based anomaly detection for in-process visual inspection of laser surface heat treatment

Publication: Machine Learning for Cyber Physical Systems, Springer, pp. 17-24

Date: November 2016

Author: B. Kamp, A. Ochoa, y J. Diaz-Rozo

Title: Smart servitization within the context of industrial user-supplier relationships: contingencies according to a machine tool manufacturer

Publication: Int J Interact Des Manuf, vol. 11, n.o 3, pp. 651-663

Date: August 2017

Author: D. Isaacs, J. Diaz-Rozo, A. Astarola, y B. Arejita

Title: Making Factories Smarter Through Machine Learning

Publication: Industrial Internet Consortium

Date: January 2017

Author: J. Diaz-Rozo, C. Bielza, y P. Larrañaga

Title: Machine learning-based CPS for clustering high throughput machining cycle conditions

Publication: Procedia Manufacturing, vol. 10, pp. 997-1008

Date: January 2017

Author: J. Diaz-Rozo, C. Bielza, J. L. Ocaña, y P. Larrañaga

Title: Development of a Cyber-Physical System based on selective Gaussian naïve Bayes model for a self-predict laser surface heat treatment process control

Publication: Machine Learning for Cyber Physical Systems, Springer Vieweg, Berlin, Heidelberg, pp. 1-8

Date: February 2016

Author: D. Atienza, C. Bielza, J. Diaz-Rozo, y P. Larrañaga

Title: Anomaly Detection with a Spatio-Temporal Tracking of the Laser Spot

Publication: Frontiers in Artificial Intelligence and Applications, pp. 137–142

Date: January 2016

Linked 3rd Party to Etxetar

IoTwins is a European project that aims to build a reference architecture for the development of efficient and distributed digital twins for specific manufacturing and facility management domains.

12 dedicated large-scale testbeds will collect large amounts of data to generate and refine the associated digital twins, including optimized models of resources, systems, and processes involved. IoTwins digital twins will be used to improve the efficiency of production processes and of facility management, as well as to demonstrate the replicability of the achieved results in similar scenarios and to determine new application areas and business models.

All the IoTwins testbeds share the same methodology: models that exploit big data and domain expert knowledge to accurately represent a complex system, such as an industrial plant, or a process, or a facility, with the ambition of predicting its temporal evolution and dynamics. The underlying technologies ground on the concept of distributed IoT-/edge- /cloud-enabled hybrid twins.

RESEARCH AND DEVELOPMENT OF AN ARTIFICIAL INTELLIGENCE-BASED METHODOLOGY ORIENTED TO PROVIDE CONTINUOUS AND ULTRA-HIGH SPEED DATA ANALYSIS IN REAL INDUSTRIAL SCENARIOS

- Public Funding Agency: Ministerio de Ciencia e Innovación y la Agencia Estatal de Investigación

- Program: Retos RTC2019-0006871-7

- Beneficiaries: Aingura IIoT, S.L. (líder), Titanium Industrial Security, S.L., Universidad Politécnica de Madrid, Universidad de la Iglesia de Deusto, Barcelona Supercomputing Center.

- Total budget: 2.864.671,20€

DEVELOPMENT OF A DIAGNOSTIC SYSTEM BASED ON MACHINE LEARNING FOR REAL TIME DETECTION OF EARLY DEGRADATION IN THE PHARMACEUTICAL MANUFACTURING PROCESS.

- Objective: The MLpharma project seeks to develop and implement, at the prototype level, a solution based on Machine Learning that allows the detection of deviations that may negatively affect pharmaceutical production processes to be detected in real time. This solution will improve the performance of maintenance activities, allowing the production elements causing these deviations to be detected. It will also allow online system efficiency monitoring, since the system will have the capacity to detect quality problems caused by anomalous deviations, enabling the decision making without having to wait to detect it at the end of the production cycle, generally several days.

- Result: the final result will be a solution based on Machine Learning for data streams implemented on an Aingura Insights Edge Computing node that can be deployed in productive environments in the pharmaceutical sector for real-time monitoring and anomaly detection.

- Public Financing Agency: Entidad Pública Empresarial Red.es

- Program: Convocatoria de Ayudas 2020 sobre Desarrollo Tecnológico basado en Inteligencia Artificial y otras Tecnologías Habilitadoras Digitales C0007/20-ED (2020/0720/00099369)

- Beneficiaries: Aingura IIoT, S.L.

- Total budget: 237.529,43€

Industrial Cluster Flexibility Platform for Sustainable Factories to Reduce CO2 Emissions and to Enable the Energy Transition

To achieve the goals of the EU Green Deal as well as the national energy agendas, an increasing need for flexibility to compensate for fluctuating generation from renewable energy sources is needed. The industrial sector as one of the largest consumers of energy has a mostly untapped potential of flexibility provision.

Increased flexibility of industrial production processes combined with on-site energy supply and storage technologies can offer new opportunities to improve sustainability of industrial sites and help integrate more renewable sources in the power grid. However, there are still some challenges to be tackled: tools need to be developed to better integrate energy storage solutions and renewable sources into industrial settings. Furthermore, solutions linking the flexibility potential of industrial sites with surrounding community and energy markets as a whole need to be developed to enable the realization of new business models.

FLEX4FACT will accompany industrial partners in achieving their energy transition by developing digital tools integrated in a holistic platform, thus paving the way for industrial flexibility provision benefiting various stakeholders along the value chain. This will increase the penetration of renewable sources, which will in turn decrease the dependency on energy fuels and reduce the energy bill of EU enterprises, leading to a competitive EU industry.

RESEARCH AND DEVELOPMENT OF SOLUTIONS BASED ON 5G/6G WIRELESS COMMUNICATION AT THE EDGE FOR THE DEPLOYMENT OF UBIQUITOUS ADVANCED ANALYSIS BASED ON ML FOR CRITICAL SECTORS, WITH REAL USE CASES WHERE BANDWIDTH, SUSTAINED FLOWS, AND LOW LATENCY ARE CRITICAL

- Executive Summary: Aingura IIoT has been at the forefront of Edge Computing since 2016, holding the first patent for industrial Edge solutions (US10031500B1). The approach focuses on computing data near its source, reducing data acquisition times from seconds to microseconds, where bandwidth, continuous flows, and low latency are critical. With the advent of 5G and 6G, Aingura is advancing real-world solutions in industrial environments where wired infrastructure is impractical or costly, such as factories, airports, and civil infrastructures. By integrating Aingura Insights nodes with advanced interconnectivity, they aim to create a federated system of distributed computing for Machine Learning, enabling cooperative processing across similar devices. By late 2022, Aingura will have a 5G laboratory with Ericsson and Vodafone equipment to further research the deployment of 5G/6G networks, supercomputing, and federated learning in industrial scenarios with significant economic impact. As part of this project, the company will evaluate key parameters of the new 5G SA network, configure network settings for Aingura Insights clusters, define the foundations for future federated intelligence capabilities, and develop industrial use cases involving high data flow and low latency.

- Public Financing Agency: Unión Europea – NextGenerationEU y Ministerio para la Transformación Digital y de la Función Pública a ytravés del Plan de Recuperación, Transformación y Resiliencia.

- Program: UNICO I+D 5G-6G 2022: Programa de Universalización de Infraestructuras Digitales para la Cohesión (Infraestructuras de investigación, equipamiento científico técnico y Proyectos de I+D en 5G Avanzado) TSI-064200-2022-16

- Beneficiaries: Aingura IIoT, S.L.

- Total budget: 498.653€

New Solutions based on Artificial Intelligence for the efficiency and flexibility of industrial production [INDUSTR-IA]

- Executive Summary: The project "New Artificial Intelligence-Based Solutions for the Efficiency and Flexibility of Industrial Production" aims to revolutionize the competitiveness of the industrial sector through more general, explainable, and accessible Artificial Intelligence (AI) models, complemented by digital twins. These models seek to simultaneously improve production, maintenance, and quality, while also integrating the energy dimension to optimize the use of renewable energy and participation in energy flexibility markets. Implementation will rely on an IIoT architecture distributed across Edge, Platform, and Enterprise layers, incorporating sensors, AI algorithms, and systems such as EMS and MES enhanced with AI to enable efficient decision-making and advanced industrial planning. The project will be carried out over four years and is structured into six key activities: dynamic planning and sequencing, design of digital twins, predictive maintenance, energy efficiency in industrial buildings, research and development of the virtual platform, and validation through use cases. To achieve these ambitious goals, a robust consortium has been formed, combining the theoretical knowledge of universities and research institutions (such as UNIOVI, BSC, and UPM) with the practical expertise of technology centers, tech SMEs, and large industrial companies (Aingura IIoT, Etxetar, ZEO, Neinsa, Ecointegral, and Plexigrid). This multidisciplinary collaboration will allow for modular or integrated implementation of the results, maximizing their impact on the digital and sustainable transformation of the industry.

- Public Financing Agency Companies: Centre for the Development of Industrial Technology and Innovation (CDTI).

- Public Financing Agency Universities: Agencia Estatal de Investigación (AEI)

- Program: SCIENCE AND INNOVATION MISSIONS 2023, TRANSMISiONES MIG-20232016/PLEC2023-010252

- Beneficiaries CDTI: Aingura IIoT, Etxetar, ZEO, Neinsa, Ecointegral y Plexigrid.

- Beneficiaries AEI: UPM, BSC and UNIOVI

- Total budget: 3.449.486,00 € (CDTI), 1.623.003,60 (AEI).