.png)

13.07.2020 | Features and technology

As ball-bearings are critical elements of all rotating machines, continuous health monitoring of them helps to reduce unexpected machine downtimes. However, it is not an easy task as ball-bearings in real world are embedded in places where noise masks the measurement, specifically when using accelerometers.

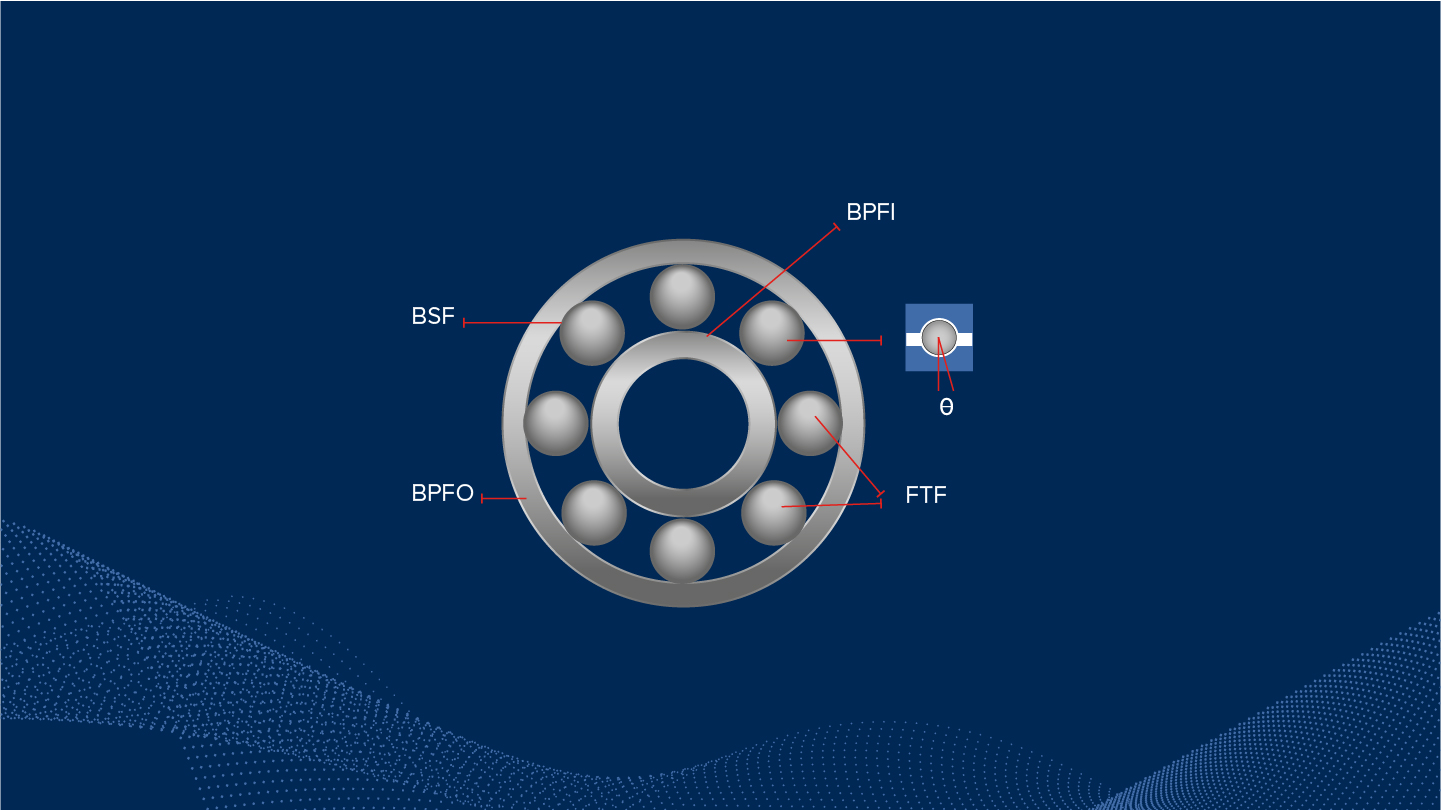

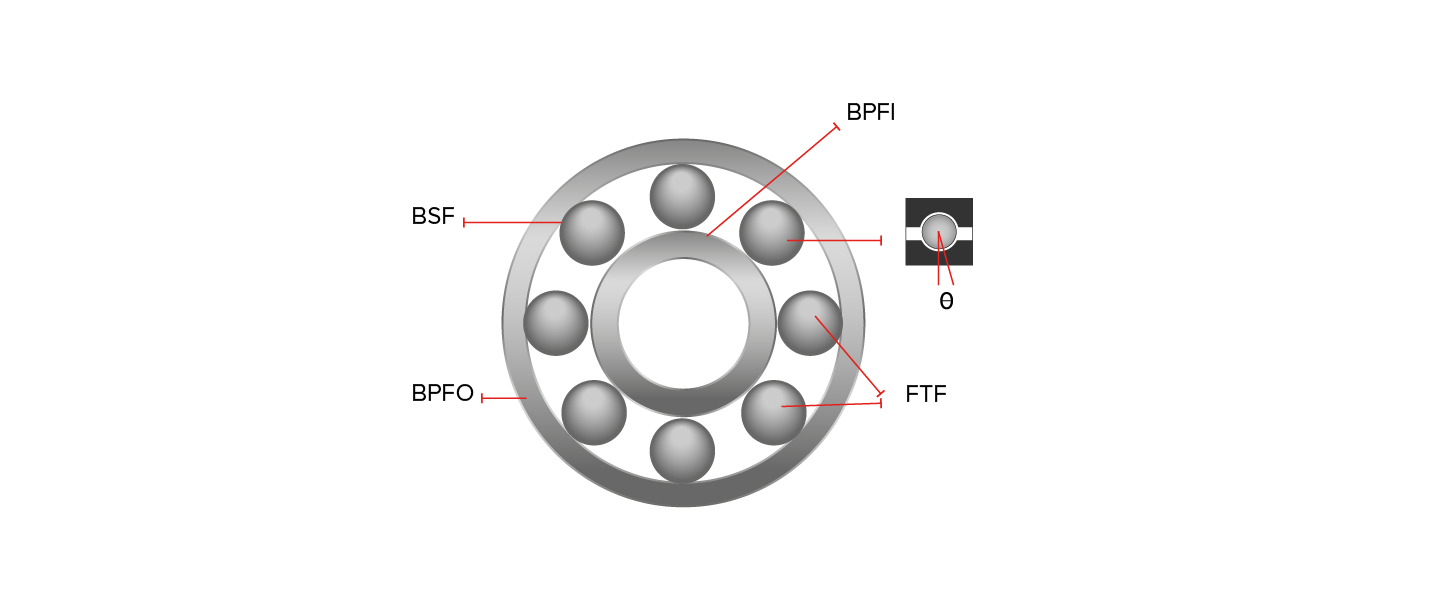

Additionally, traditional measurement approaches, based on acceleration, required certified expertise from the maintenance technician, becoming extremely difficult to automate and enable online (non-stop) analysis. Ball-bearings are made little components such as rings, cages and balls oscillating at well-known frequencies. A key approach is to monitor those frequencies separately to detect early failures that affects ball-bearing health. Nevertheless, their amplitudes are below noise coming from other mechanical and electrical noise.

Once the signal is filtered, proprietary techniques, which search in the spectrum, are used to extract ball-bearing amplitudes of such impulses. In order to work in real industrial environments, the algorithm needs to meet the following requirements: It has to deployed in Edge computing nodes with limited computing power It has to be isolated from processes that may induce coupled vibrations such as a tool during a machining operation with extremely low time windows available, below 1 second. for the measurements are extremely low.

Aingura IIoT development team in collaboration with Barcelona Supercomputing Center has set into operation the algorithm in real industrial case. To meet measuring requirements, we have optimized the algorithm to be deployed into our Edge computing node, Aingura Insights. The result has been a 13x acceleration from the algorithm original version.

|

|

|

Figure 2. Aingura Insights computing node

|

Figure 3. IEPE-based sensor interface (accelerometer) used to deploy ball-bearing algorithm.

|

For more information, please contact us at info@ainguraiiot.com