impact

- Potential Improvement in energy efficiency between 7% and 10% depending on equipment.

- Potential improvement in energy consumption by 15% approx. in support systems such as cooling.

Developed AI Technologies

Pattern analysis, prediction and intelligent classification.

Challenges

- To find the power consumption pattern of the aluminum melting towers to detect possible improvements in the use of mixed raw material.

results

- Dataset size: 200 MB

- Number of variables: 10

- Sampling time: 1s

- By means of clustering techniques by Gaussian mixtures, it has been possible to detect the energy consumption of gas according to the raw material mixture.

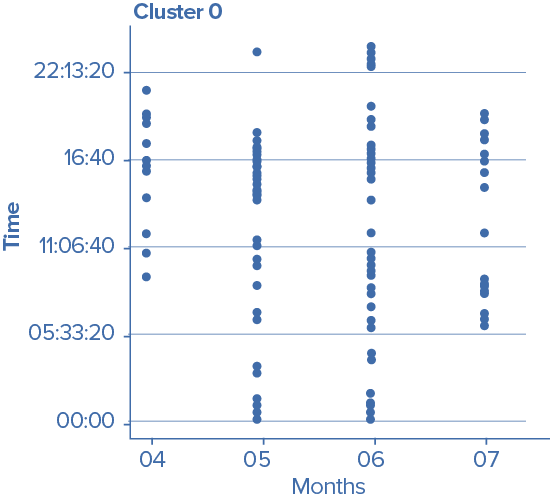

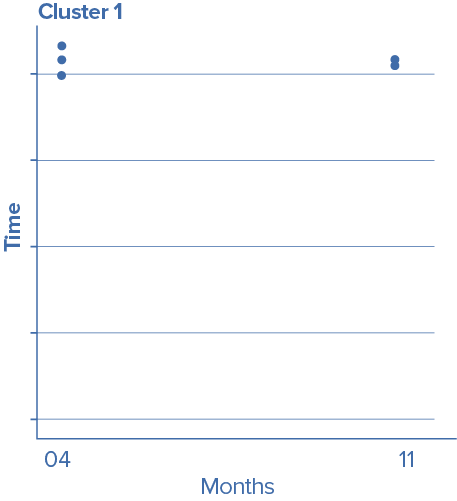

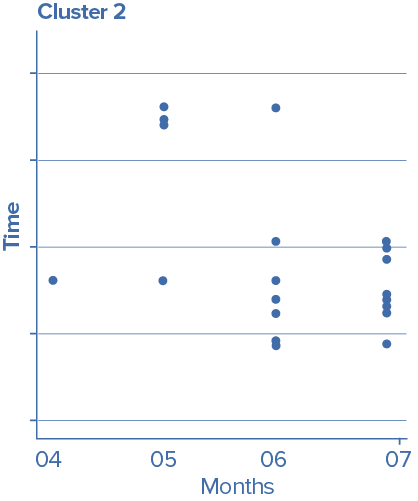

Figure 15. Data clustering from one of the fusion towers

- The average values, in this case, the centroids of each cluster, have been able to differentiate the 3 different groups of the most relevant average foundry mix when it comes to gas consumption.

- Additionally, a temporal analysis allows analyzing the clusters with the highest energy consumption, in the case of Figure 16, Cluster 1 is the one with the most important deviations, detailing the time slot in which it occurs.

|

|

|

Figure 16. Temporal analysis of fusion tower.