impact

- Potential reduction of unscheduled shutdowns (80%).

- Potential reduction of preventive maintenance cost (50%).

- Potential reduction of corrective maintenance cost (20%).

ARTIFICIAL INTELLIGENCE (AI) TECHNOLOGIES DEVELOPED

- Novelty Detection Techniques: Utilizing advanced novelty detection methods to identify anomalies and deviations in the performance of centrifugal pumps.

- Online AI-Driven Baseline Generation: Employing AI algorithms to continuously generate and update baseline data for real-time comparison with current pump performance.

- Probability-Based AI Technology: Implementing probability-based AI models to assess the likelihood of component failure or degradation.

- Unique KPI Representing Overall Behavior: Creating a distinctive Key Performance Indicator (KPI) that offers a comprehensive view of the centrifugal pump's overall performance and behavior.

- Online Feature Subset Selection: Employing online feature subset selection techniques to extract the most relevant and informative features for accurate condition assessment in real-time.

Developed AI Technologies

Challenges

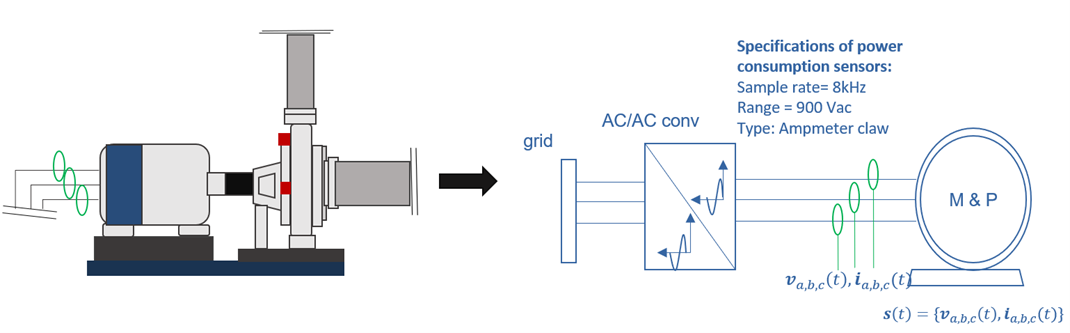

- Develop a nonintrusive sensor system for data collection from centrifugal pumps.

- Create a comprehensive dataset from limited available information about the analyzed system.

- Implement advanced data preprocessing techniques to clean and format the collected data.

- Explore novel feature engineering methods to extract relevant information.

- Apply machine learning algorithms to develop a KPI that can effectively monitor the health of centrifugal pumps.

- Ensure the KPI is capable of detecting anomalies or faults in real-time or near-real-time.

- Establish a threshold or baseline for the KPI to trigger alerts when anomalies are detected.

- Integrate the KPI into the existing monitoring system for seamless deployment and operation.

- Validate the KPI's accuracy and reliability through testing and performance evaluation.

- Provide actionable insights and recommendations for maintenance and corrective actions based on KPI alerts.

results

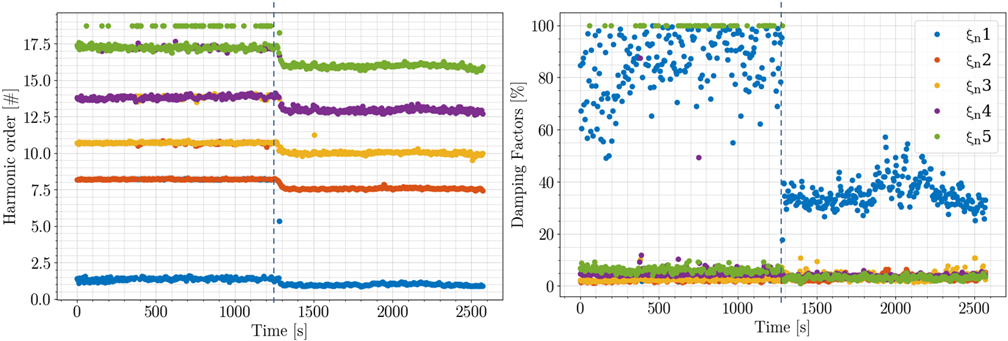

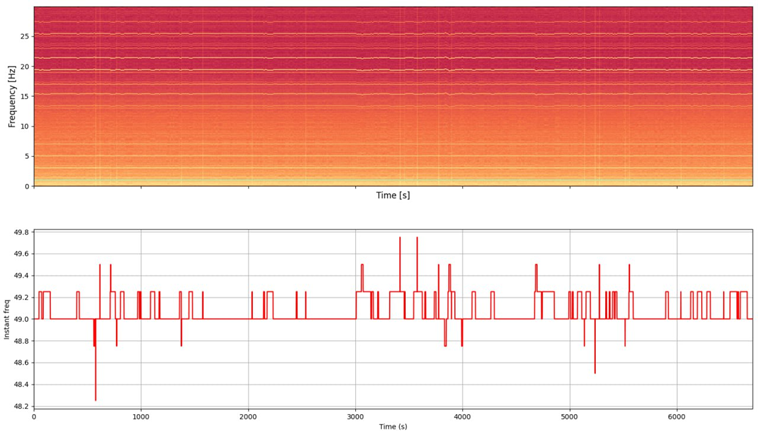

- Generation of an explainable model that accurately represents the dynamic behaviour of the electrical and mechanical system of the pump.

- Extraction of modal parameters that are highly correlated with the natural modes of the analyzed system, providing interpretable information to the end user for diagnosing abnormal operation.

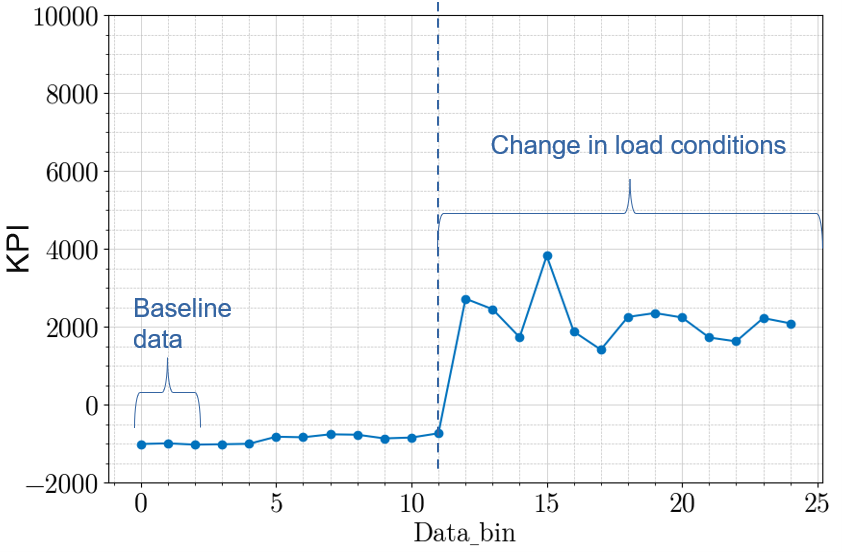

- Utilization of the estimated modal parameters to create a probabilistic machine learning baseline, which in turn produces a Key Performance Indicator (KPI) that signifies the healthy state of the pump's operation.